HL型环链离心斗式提升机适用于垂直输送磨琢性较大的粉状、粒状、及小块状物料,如粮食、煤、水泥、碎矿石等,输送高度最高40m。其特点为,结构简单,运行平稳,掏取式装料,混合式或重力卸料,轮缘采用组合链轮,更换方便,链轮轮缘经特殊处理寿命长,下部如采用重力自动张紧装置,能保持恒定的张力,避免打滑或脱链,同时在料斗遇阻时,有一定的容让性能够有效地保护运动部件,物料温度不超过250℃。

Product overview

The HL type centrifugal bucket elevator chain is suitable for vertical conveying grinding cut larger powder, granulated and small lump materials, such as grain, coal, cement, crushed ore, conveying height top 40 m.For its characteristics, simple structure, smooth operation, tao take type charging, mixed or gravity discharge, rim combined sprocket, easy to change, sprocket rim specially dealing with long service life, lower if use gravity automatic tensioning device, can keep constant tension and avoid skid or take off the chain, in the hopper blocked at the same time, has the certain let performance enough to effectively protect the moving parts, material temperature does not exceed 250 ℃.

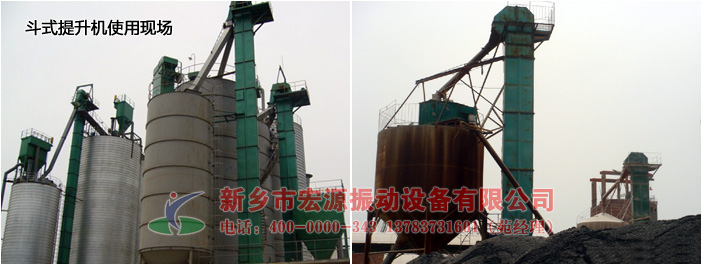

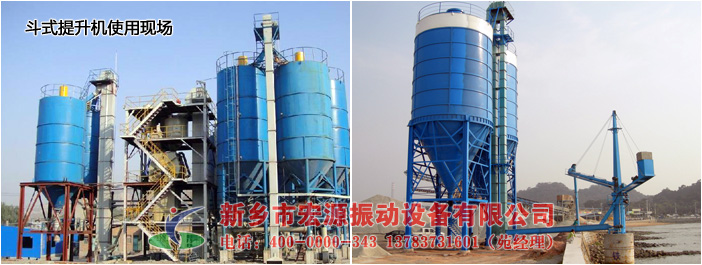

Working site

1.运行平稳、输送效率高。

2.料斗形式多,应优先选用。

3.适应性强、安装维修方便、寿命长。

4.整机体积小、转速高、确保快速均匀输送。

Features

1. Smooth operation, high transmission efficiency.

2. The hopper form, more should be preferable.

3. Strong adaptability, easy installation and maintenance, long service life.

4. The machine is small in size, high speed, ensure rapid delivery uniformity.

我公司生产的HL型环链离心斗式提升机由运动部分(料斗与牵引链条)、带有传动链轮的上部区段、带有拉紧轮的下部区段、中间机壳、驱动装置、逆止制动装置等组成(见下图)。本提升机的料斗为间断式布置,利用“掏取法”进行装载,“离心投料法”卸料。本提升机的牵引机构是两根环形链条。

Working principles

Our company produces the HL type centrifugal bucket elevator chain by moving parts (hopper and traction chain), with the upper section of the sprocket, with the bottom of the tensioning wheel section, intermediate casing, driving device, non-return braking device, etc (see below).The hoist hopper for layout, intermittent loading by determining the 'tao', the 'centrifugal feeding method' discharge.This elevator traction institutions are two circular chain.

1、按料斗形状分为两种:S制法--带有深圆底形料斗;Q制法--带有浅圆底形料斗。

2、按上部区段卸料口的形式分为两种:X1 制法--带有倾斜法兰的卸料口;X2 制法--带有水平法兰的卸料口。

3、按下部区段进料口的形式分为两种:J1 制法--进料口的斜面与水平面成45度角;J2 制法--进料口的斜面与水平面成60度角。

4、按中间机壳侧面检视门的位置分为四种:K1 制法--中间机壳侧面带有下端左检视门;K2 制法--中间机壳侧面带有下端右检视门;K3 制法--中间机壳侧面带有上端左检视门;K4 制法--中间机壳侧面带有上端右检视门。

5、按中间机壳端面检视门的位置分为两种:Z1 制法--中间机壳端面带有下端检视门;Z2 制法--中间机壳端面带有上端检视门。

6、按传动装置对提升机的相对位置分为两种:左装--传动装置在左侧;右装--传动装置在右侧。

Manufacture and Assemble Method

1, according to the shape of hopper is divided into two kinds: S method -- with a deep round bottom shaped hopper;The method of Q - with shallow round bottom shaped hopper.

2, according to the upper section of the form of a discharge outlet can be divided into two kinds: X1 fashion - with the discharging mouth of the inclined flange;Method the X2 - with horizontal discharge outlet flange.

3, according to the form of lower section inlet can be divided into two kinds: J1 program - inlet of inclined plane and horizontal plane Angle of 45 degrees;J2 method - inlet of inclined plane and horizontal plane into 60 degree Angle.

4, according to the intermediate casing side view of the position of the door is divided into four kinds: K1 process - intermediate casing with the bottom left side view door;K2 method -- intermediate casing with the bottom right side view door;K3 method -- intermediate casing with the upper left side view door;K4 method - intermediate casing with the top right side to check door.

5, according to the intermediate casing end view of the position of the door is divided into two kinds: - Z1 know-how for the intermediate casing end with a bottom view door;Method Z2 - intermediate casing end face with top view door.

6, according to the transmission of the relative position of hoist is divided into two kinds: left - transmission device on the left side;Right - transmission device on the right side.

Outline Sketch map

Parameters

| 项 目 | 提升机型号 | ||||||||

| HL300 | HL400 | ||||||||

| S制法 | Q制法 | S制法 | Q制法 | ||||||

| 输送能力,平方米/小时 | 28 | 16 | 47.2 | 30 | |||||

| 料斗容量,升 | 5.2 | 4.4 | 10.5 | 10 | |||||

| 斗距,毫米 | 500 | 500 | 600 | 600 | |||||

| 运行部分(料斗牵引链条) 公斤/米 | 24.8 | 24 | 29.2 | 28.3 | |||||

| 牵引链条 | 型式 | 锻造环形链 | |||||||

| 圆钢直径(毫米) | 18 | 18 | |||||||

| 节距(毫米) | 50 | 50 | |||||||

| 破断强度(公斤) | 12800 | 12800 | |||||||

| 料斗运动速度(米/秒) | 1.25 | 1.25 | |||||||

| 传动链条轴转数(转/分) | 37.5 | 37.5 | |||||||

| 输送物料的散状比重 | H,米 | N,千瓦 | H,米 | N,千瓦 | H,米 | N,千瓦 | H,米 | N,千瓦 | |

| 0.8 | 59 | 6.35 | 64 | 4.36 | 30 | 7 | 33 | 6.3 | |

| 1.0 | 52 | 7.55 | 60 | 5.12 | 27 | 7.6 | 30 | 7 | |

| 1.25 | 41 | 8.7 | 49 | 5.3 | 23 | 8 | 26 | 7.6 | |

| 1.6 | 31 | 9.7 | 39 | 5.3 | 18.5 | 8.4 | 22 | 8.2 | |

| 2.0 | 24 | 9.7 | 29 | 5.35 | 15 | 8.6 | 18 | 8.4 | |

| 传动装置制法 | C1 | C2 | C3 | C4 | C1 | C2 | |||

| 圆柱齿轮减速机 | 传动装置右装 | JZQ400―IV―3U | JZQ400―IV―3U | ||||||

| 传动装置左装 | JZQ400―IV―4Y | JZQ400―IV―4Y | |||||||

| 电动机型号 | Y132M2―6 | Y160M―6 | Y160L―6 | Y160M―6 | Y160L―6 | ||||

| 传动装置功率(千瓦) | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | |||

| 棘轮制动装置(齿轮X模数) | 6X18 | 6X18 | 8X15 | 8X15 | 6X18 | 8X15 | |||

| 传动装置重量(公斤) | 628 | 702 | 870 | 885 | 902 | 917 | |||

| 物料的最大块度(毫米) | 25 | 35 | 45 | 55 | |||||

斗式提升机作为一种常用的提升设备,在得到广泛应用的同时,根据不同行业的要求也有着非常清楚的分类,按照传动结构可以分为:

(1).TD系列斗式提升机:

TD系列斗式提升机是一种国家标准的斗式提升机,该系列斗式提升机和D系列斗式提升机都是采用的胶带传动来提升物料,两者没有本质的区别,D系列斗式提升机产品型号较老且型号规格少。TD系列斗式提升机是在D系列斗式提升机的基础上经过产品改良而来,其规格有TD100(不常用)、TD160、 TD250、TD315、TD400、TD500、TD630、TD800、TD1000等型号,其中TD160、TD250、TD315等型号为普遍采用型号.

(2).TH系列斗式提升机:

TH系列斗式提升机是一种常用的提升设备,该系列斗式提升机采用锻造环链作为传动部分,具有很强的机械强度,主要用于提升粉体和小颗粒及小块状物料,区别于TD系列斗式提升机,其提升量更大、运转效率更高。其常用于较大比重物料的提升。

(3).NE系列斗式提升机:

NE系列斗式提升机是一种新型的斗式提升机,其采用板链传动,区别于老型号TB系列板链斗式提升机,其命名方式采用提升量命名而非斗宽。如NE150指的是提升量为150吨一小时而不是斗宽150。NE系列斗式提升机有着很高的提升效率,根据提升速度不同还分有NSE型号及高速板链斗式提升机。

(4).TB系列斗式提升机:

TB系列斗式提升机是一种较老型号的斗式提升机,其传动部分采用板链传动,现已经被NE系列斗式提升机产品替代。

(5).TG系列斗式提升机:

TG系列斗式提升机是一种加强型胶带斗式提升机,区别于TD系列斗式提升机,TG系列斗式提升机采用钢丝胶带作为传动带,具有更强的传动能力。该系列斗式提升机多被应用于粮食输送上,又被称呼为粮食专用斗式提升机。

(6).其它型号斗式提升机:

常见的斗式提升机型号还有HL系列斗式提升机、GTD系列斗式提升机、GTH系列斗式提升机等,其均为以上型号的不同叫法和演变形式。

Kinds of classification

Bucket elevator, as a commonly used lifting equipment, is widely applied in the at the same time, on the basis of the requirements of different industries have a very clear classification, according to the transmission structure can be divided into:

(1). TD series bucket elevator:

TD series bucket elevator is a kind of national standard of bucket elevator, the series bucket elevator and D series bucket elevator are the tape drive to improve material, no essential difference between the two, D series bucket elevator product model relatively less old and specifications.TD series bucket elevator is on the basis of the D series bucket elevator after product improvement, and its specifications have TD100 (not used), TD160, TD250, TD315, TD400, TD500, TD630, TD800, TD1000 models, including TD160, TD250, TD315 model for the widely used model.

(2). TH series bucket elevator:

TH series bucket elevator is a commonly used lifting equipment, the series bucket elevator forged ring chain as the driving part, has a strong mechanical strength, it is mainly used for lifting powder and small particles and small block material, different from TD series bucket elevator, the lifting capacity is bigger, more efficient operation.The materials commonly used in larger proportion of ascension.

(3). NE series bucket elevator:

NE series bucket elevator is a new type of bucket elevator, it USES the plate chain, different from the old models TB series plate chain bucket elevator, named after its aming users lifting capacity rather than fight wide.Such as NE150 refers to the lifting capacity of 150 tons a sometimes not fight 150 wide.NE series bucket elevator has a high efficiency, according to the speed of different points are also NSE model and high-speed plate chain bucket elevator.

(4). The TB series bucket elevator:

TB series bucket elevator is a kind of older types of bucket elevator and its transmission part adopts plate chain, now replaced by NE series bucket elevator products.

(5). TG series bucket elevator:

TG series bucket elevator is a kind of reinforced belt bucket elevator, the difference in the TD series bucket elevator, TG series bucket elevator adopts steel wire adhesive tape as a transmission belt, have stronger ability of transmission.This series bucket elevator is more applied in food delivery, and called for food special bucket elevator.

(6). Other types of bucket elevator:

Common bucket elevator model number and the HL series bucket elevator, GTD series bucket elevator, GTH series bucket elevator, etc., and its form are the above model and different way of evolution.

我公司可根据用户需要设计制造特殊型号规格的斗式提升机。

我公司对所有技术资料、尺寸保留修改的权利,如实物与文中图案不符,应以实物为准。

Our company can design and manufacture according to user needs special specifications of bucket elevator.

My company for all technical data, reserve the right to modify the size, such as material object does not accord with the design, the material shall prevail.