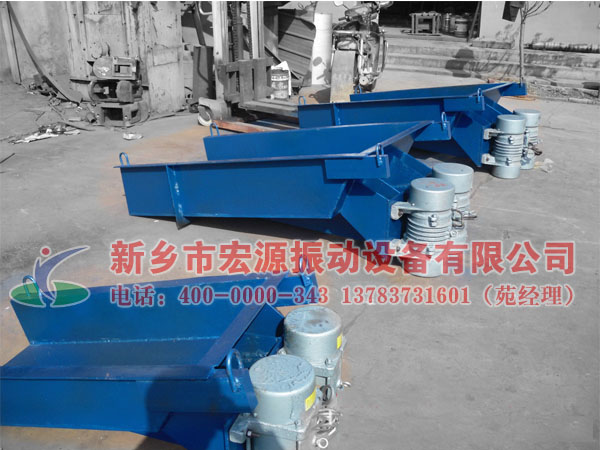

Working site

Parameters

1、振动给料机如用于配料、定量给料时,为保证给料的均匀稳定,防止物料自流,应水平安装。如进行一般物料连续给料,可下倾10°安装。对于粘性物料及含水量较大的物料可以下倾15°安装。GZG型电机振动给料机安装与调试、使用与维护

2、安装后的给料机应留有20mm的游动间隙,横向应水平,悬挂装置采用柔性连接。

3、空试前应将全部螺栓紧固一次,尤其是振动电机的地脚螺栓,连续运转3-5小时应重新紧固一次。

4、试车时,两台振动电机必须反向旋转。

5、给料时在运行过程中应经常检查振幅,电流及噪音的稳定性,发现异常应及时停车处理。

6、电机轴承每2个月加注一次润滑油,高温季节应每月加注一次润滑油。

1, vibrating feeder, such as used for ingredients, quantitative feeding, to ensure the uniform stability of feed, prevent complete material and should be installed.Such as general continuous feeding material, can install downdip 10 °.For larger viscous material and water content of the material can be installed downdip 15 °.GZG type motor vibrating feeder installation and debugging, using and maintenance

2, after the installation of feeder should swim with 20 mm of clearance, transverse level, suspension device adopts flexible connection.

3, empty before try all bolts should be a, especially the vibration motor anchor bolt, continuous operation shall be retightened 3 to 5 hours.

4, commissioning, two vibrating motors must reverse rotation.

5, when the feed in the process of operation should be regularly check the amplitude, the stability of the current and noise, find parking exceptions should be timely treatment.

6, motor bearing once every 2 months filling of lubricating oil, high temperature season should be filling lubricating oil once a month.

1、生产率的确定:本系列电机振动给料机的生产率是以河砂为标准物料给出的(堆比重为1.6T/m3)。当物料堆比重大于1.6T/m3时,其产量可按额定值选取;当物料的堆比重在1.2~1.6T/m3时,其产量可达到额定产量的0.9~1.0倍;当物料堆比重在0.8~1.2T/m3时,其产量可达到额定值的0.8~0.9倍。物料堆比重小于1.6T/m3时,须适当增加料层厚度,以提高产量。对于振动给料机难于输送的物料(如滑石粉、钛白粉、白泥、面粉、粘土等),以及含水量较大的亲水性物料,则应根据试验确定产量。必要时将槽体适当倾斜安装(一般向下倾斜10~15度),以增加给料量。

2、控制箱的选择:本系列电机振动给料机配套控制箱为反接制动控制箱,它可使给料机在停车时,快速停机,使给料机迅速通过共振区,避免过大振幅对机器造成损害。该控制箱具有过流、过压、断相等保护功能,另可根据工艺要求,增加能耗制动、快慢加料、远程控制及无级调速等功能。用户在订购时请注明。

3、给料机使用条件:

(1)环境温度不超过+40℃;

(2)在环境温度为20±5℃时,周围介质相对湿度不大于85%;

(3)周围没有严重腐蚀及影响电气绝缘的介质。

4、如在选型时遇到空间距离限制宽度,可考虑将振动电机改为后置安装,减小宽度尺寸。

温馨提示:GZG系列电机振动给料机由于常应用于各种特定给料场合,其外形尺寸一般根据买方实际要求设计生产,以满足各种给料量及场地安装要求。该系列振动给料机常用为挂式,根据应用场合不同,可以选用钢制弹簧或者是橡胶弹簧。该系列振动给料机也可以座式安装,也可以加装棒条、高耐磨衬板等作为放矿机使用。其具有灵活多变的使用方式,上述参数仅为常用情况下参数,具体情况请咨询本公司技术人员。

Equipment selection considerations

1, the determination of productivity: this series of motor vibration feeder river sand material on the productivity of the given (bulk density of 1.6 T/m3).When the material bulk density is greater than 1.6 T/m3, its output according to rating the selection;When the material bulk density in 1.2 ~ 1.6 T/m3, the yield can reach 0.9 ~ 1.0 times of the rated output;When the material bulk density in 0.8 ~ 1.2 T/m3, the yield can reach 0.8 ~ 0.9 times of rating.Material bulk density is less than 1.6 T/m3, shall be appropriately increased material layer thickness, in order to improve the yield.For vibrating feeder is difficult to transport materials (such as talcum powder, titanium dioxide, white clay, flour, clay, etc.), as well as the water content of hydrophilic material, should be determined according to test production.Necessary tub tilt appropriate installation (the general tip down 10 ~ 15 degrees), in order to increase quantificationally.

2, the choice of control box: this series of motor vibration feeding machine control box to reverse connect braking control box, it can make the feeding machine when parking, fast down, take the feeder rapidly through the resonance area, avoid too large amplitude cause damage to the machine.The control box has over-current, over-voltage, equal protection function, the other according to the technological requirements, increase the braking energy consumption, fast charging, remote control and stepless speed regulation, and other functions.When ordering please indicate the user.

3, feeder conditions of use:

(1) the environment temperature is not more than + 40 ℃;

(2) when the environment temperature is 20 + / - 5 ℃, ambient relative humidity is not more than 85%;

(3) there is serious corrosion and the influence of electrical insulating medium.

4, such as the selection when space distance limit width, can consider to install the vibration motor to the rear, to decrease the size of width.

Warm prompt: because GZG series motor vibrating feeder often used in a variety of specific feeding occasions, its overall dimensions general design production according to the buyer of the actual requirements, to meet all kinds of quantificationally and site installation requirements.This series of vibrating feeder are commonly used for hanging, according to different applications, can choose steel spring or rubber spring.This series of vibrating feeder can also be a type installation, can also be equipped with the rods, high abrasion resistant lining board used as drawing machine.It has the use of a flexible way, the above parameters only for common cases, specific circumstances please consult technical personnel of the company.

下振式:振动电机置于给料机下面;

上振式:振动电机置于给料机上面;

调速式:振动电机的振频可在0--额定频率范围内无级调速度;

敞开式:给料机上面敞开,比较适合下振式;

密封式:给料机除进出料口外,全部密封;

基座式:对于大型(重型)给料机,一般采用座式结构.

另我公司还可根据您的生产要求,为您订做各种型号给料机。

Customized

Under vibration type: vibrating motor positioned below the feeder;

On the vibration type: vibrating motor placed above the feeder;

Speed: vibration frequency of the vibrating motor is within 0 - rated frequency stepless adjustable speed;

Open: feeder open above, to suit the type of vibration;

Sealed: except for the feeder front-rear outlets, all sealed;

Base type: for large (heavy) feeder, generally USES a type structure.

The other we also can according to your production requirements, customized for your various types feeder.

★我公司可根据用户需要设计制造特殊型号规格的振动给料机。

★我公司对所有技术资料、尺寸保留修改的权利,如实物与文中图案不符,应以实物为准。

★ my company can design and manufacture according to user needs special specifications of vibrating feeder.

★ for all my company reserves the right to modify technical data, size, such as material object does not accord with the design, the material shall prevail.