大倾角皮带式输送机广泛用于煤炭、冶金、建筑、粮食、化工、电力等部门。大倾角带式输送机具有通用带式输送机结构简单、运行可靠,维修方便等优点,具有可大倾角(90度垂直)输送、结构紧凑、占地少等特点,输送倾角为0°~90°范围内,最大垂直输送物料粒度为400mm。大倾角带式输送机是大倾角(或垂直)输送的理想设备。通过多年的不懈努力,大倾角皮带机提升高度(最高已达203m)、大输送能力(最大已达6000t/h),在井下采矿工程、露天采矿、大型自卸船等方而都有所采用,并在国内首创用于钢厂的高炉上料产生了良好的经济效益。

Product overview

Big dip angle belt conveyor is widely used in coal, metallurgy, construction, food, chemical, electricity and other departments.Big dip Angle belt conveyor with the general belt conveyor of simple structure, reliable operation, convenient maintenance etc, and has large angle (90 degrees) vertical transmission, compact structure, covers an area of less, within the scope of transmission angle of 0 ° ~ 90 °, the maximum vertical conveying material particle size is 400 mm.Big dip angle belt conveyor is angle (or vertical) an ideal equipment.After years of unremitting efforts, big dip angle belt conveyor hoisting height (maximum 203 m), large transmission capacity (maximum 6000 t/h), underground mining engineering, open-pit mining, large self-unloading vessels such as parties, have been adopted, and in the domestic first used in steel mills produced good economic benefit of blast furnace.

大倾角皮带输送机使用现场

Working site

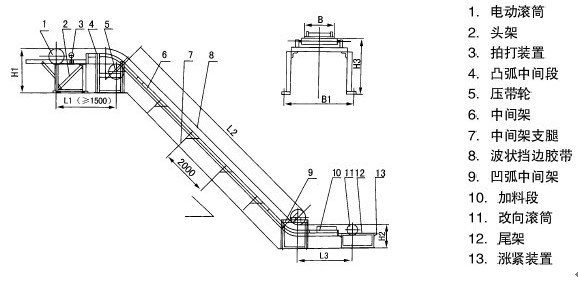

DJ型大倾角带式输送机(以下简称“大倾角”)具有通用带式输送机结构简单、运行可靠,维修方便等优点,具有可大倾角(90度垂直)输送、结构紧凑、占地少等特点,因而是大倾角(或垂直)输送的理想设备。广泛用于煤炭、冶金、建筑、粮食、化工、电力等部门。通过多年的不懈努力,大倾角皮带机提升高度(最高已达203m)、大输送能力(最大已达6000t/h),在井下采矿工程、露天采矿、大型自卸船等方而都有所采用,并在国内首创用于钢厂的高炉上料产生了良好的经济效益。

DJ type of big dip Angle belt conveyor (hereinafter referred to as the "big inclination") with the general belt conveyor of simple structure, reliable operation, convenient maintenance, with large dip Angle (90 degrees) vertical transportation, compact structure, covers an area of less, so it is (or vertical) transmission of large dip Angle of ideal equipment.Widely used in coal, metallurgy, construction, food, chemical, electricity and other departments.After years of unremitting efforts, big dip Angle belt conveyor hoisting height (maximum 203 m), large transmission capacity (maximum 6000 t/h), underground mining engineering, open-pit mining, large self-unloading vessels such as parties, have been adopted, and in the domestic first used in steel mills produced good economic benefit of blast furnace.

(1)、大倾角皮带输送机为一般用途的散状物料连续输送设备,但采用的是具有波状挡边和横隔板的输送带。因此,特别适用于大倾角及垂直90°输送。

(2)、该机可用于煤碳、化工、冶金、电力、轻工、粮食、港口等行业,在工作环境温度为-15℃~+40℃的范围内输送堆积比重为0.5―4.2t/m3的各种散状物料。

(3)、对于输送有特殊要求的物料,如:高温、具有酸、碱、油类物质或有机溶剂等成份的物料,需采用特殊的输送带。

(4)、输送倾角为0°~90°范围内,最大垂直输送物料粒度为400mm。

Applications

(1), large dip angle belt conveyor for general purpose material continuous conveying equipment, but it has a wavy guard and diaphragm plate conveyor belt.As a result, especially suitable for the large dip angle and vertical 90 °.

(2), the machine can be used in the coal industry, chemical industry, metallurgy, electric power, light industry, food, port, etc, in the work environment temperature 15 ℃ ~ + 40 ℃ within the scope of delivery the mass density of 0.5-4.2 t/m3 of loose materials for various.

(3), for conveying materials with special requirements, such as: high temperature, acid, alkali, oil substances or organic solvent such as composition of the material, the use of special conveyor belt.

(4), transmission angle of 0 ° ~ 90 °, the largest vertical conveying material particle size is 400 mm.

(1)、可大倾角输送散状物料,能大量节省设备占地面积,彻底解决普通、花纹带式输送机所不能达到的输送角度。

(2)、机械化带式输送机输送物料、总体投资费用低,约节约投资费用20%~30%。

(3)、该机型与普通带式输送机、斗式提升机、刮板输送机比较,其综合技术性能都优越。

(4)、输送量大,可达6000m3/h,垂直提升高度可达500m。

(5)、在垂直输送物料时,物料粒度最大可达400mm。

(6)、从水平到倾斜(或垂直)能平稳过渡。

(7)、能耗低、结构简单、维护方便。

(8)、胶带强度高,使用寿命长。

Features

(1), can be as big obliquity conveying material, save equipment covers an area of large, completely solve ordinary, decorative pattern cannot reach conveying Angle belt conveyor.

(2), mechanization conveying material belt conveyor, overall investment cost is low, about 20% ~ 30% investment cost saving.

(3), the aircraft with ordinary belt conveyor, bucket elevator, scraper conveyor, whose comprehensive technical performance is superior.

(4), large throughput, up to 6000 m3 / h, vertical hoisting height is 500 m.

(5), in the vertical conveying material, material particle size up to 400 mm.

(1)大倾角皮带输送机的输送倾角大,最大可达90°,是大倾角输送和垂直提升的理想设备。因此可以节约占地面积,节省设备投资和土建费用,取得良好的综合经济效益。例如,某用户欲将煤炭提升到20m高的料仓顶,如采用挡边机以45°倾角输送,则机长仅需28.3m(水平机长20m);而如果采用垂直输送的挡边机,那么,水平机长可以控制在6m以内。

(2)结构简单。如前所述,各主要部件均可与通用带式输送机通用,给使用、维修带来方便。

(3)运行可靠。没有埋刮板输送机经常出现的卡链、飘链、断链现象和斗式提升机经常发生的打滑、掉斗现象。它的可靠度几乎与通常带式输送机相等。

(4)运行平稳、噪声小。

(5)由于不存在装料时的挖掘阻力和运行时物料的内摩擦、外摩擦阻力,因此能耗小。例如,在鲁南化肥厂使用的两台提升高度各为19.28m、输送能力各为 25t/h的输送碎煤的垂直挡边机,其每台的装机功率仅4kW,而被它们所取代的四台原有埋刮板输送机的总装机功率为44kW。

(6)垂直挡边机还可以在机头和机尾设置任意长度的水平输送段,便于和其他设备衔接。

Advantages

(1) the big dip angle belt conveyor transmission angle is large, the largest up to 90 °, is an ideal equipment to transport of large dip angle and vertical ascending.So you can save area, save equipment investment and construction cost, obtain good comprehensive economic benefit.For example, a user wants to the coal up to 20 m high bunker roof, such as using guard machine with 45 ° obliquity conveying, the captain only 28.3 m (20 m) level of the pilot;Using vertical conveying rim machine, so, horizontal captain can control within 6 m.

(2) simple structure.As mentioned earlier, the main components are common with general belt conveyor, bring convenience to use and maintenance.

(3) reliable operation.Often appear no buried scraper conveyor, disconnection of chain and chain, and the bucket elevator, off the bucket of a spin occur frequently.Its reliability and usually almost equal belt conveyor.

(4) smooth operation, low noise.

Because there is no charge, (5) when the digging resistance and run-time friction materials for external and internal friction resistance, so the energy consumption is small.In southern shandong chemical fertilizer plant, for example, the use of two sets of hoisting height of 19.28 m, the conveying capacity is 25 t/h of the vertical guard crushed coal conveyor, its each installed power only 4 kw, and replaced by their four sets of the total installed power of the original buried scraper conveyer for 44 kw.

(6) vertical penal machine also can be set in the nose and tail of arbitrary length horizontal conveying section, easy to interface with other equipment.

Parameters